Products Description

"Boost Your Aquaculture Efficiency with Our Twin Screw Fish Food Machine!

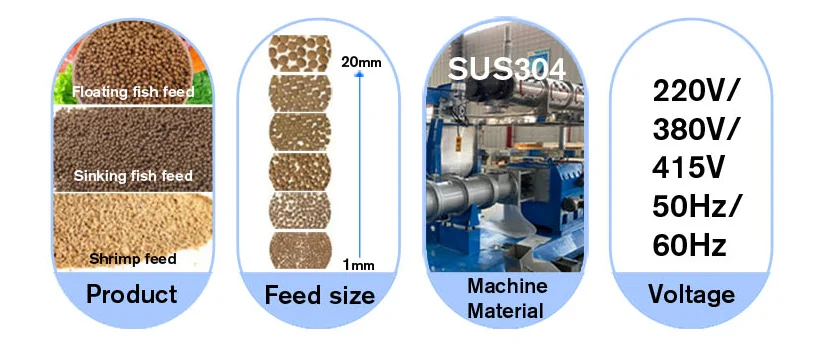

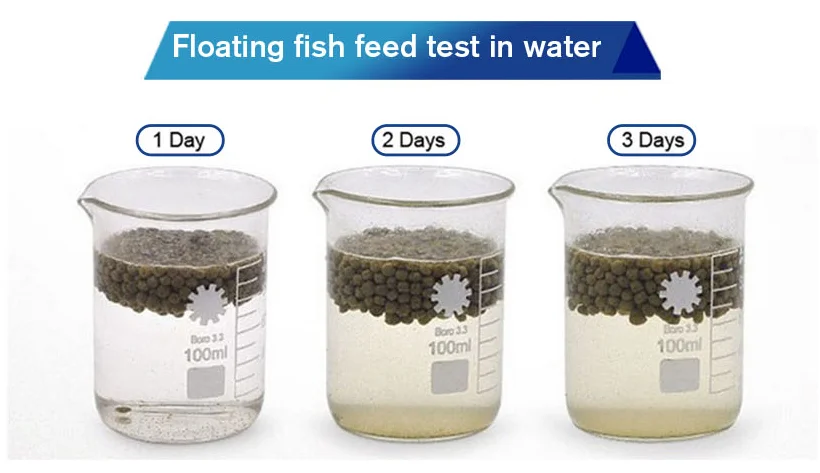

Designed for high-performance feed production, our twin screw fish food machine delivers superior mixing, cooking, and extrusion in one seamless process. Perfect for floating, sinking, or semi-floating pellets, this advanced extruder ensures uniform texture, optimal nutrition, and excellent water stability-ideal for fish, shrimp, and other aquatic species.

1️⃣ Twin-Screw Extruder – The core unit with co-rotating screws for superior mixing, cooking, and shaping of feed.

2️⃣ Conditioning System – Pre-mixes and steams raw materials for better gelatinization.

3️⃣ Cutting Mechanism – Precision pellet cutter for uniform size adjustment (1-10mm).

4️⃣ Air Conveyor – Transports and cools pellets post-extrusion.

5️⃣ Oil Sprayer – Adds coatings for enhanced nutrition and water resistance.

6️⃣ Control Panel – Automated operation with temperature and speed regulation.

Company Information

Hot Tags: twin screw fish food machine, China, suppliers, manufacturers, factory, wholesale, buy, price, for sale

Technical Parameters

|

Name |

Installed Power (KW) |

Real Consumption (KW) |

Output (kg/h) |

Size(M) |

|

FLD65 |

70 |

50 |

120-150 |

20x 2.0 x 3.0 |

|

FLD70 |

110 |

80 |

250-300 |

25x 2.0 x 3.0 |

|

FLD85 |

200 |

160 |

500-600 |

32x 2.0 x 4.0 |

|

FLD90 |

220 |

155 |

1000-1500 |

40x 2.0 x 5.0 |

|

FLD100 |

300 |

210 |

2000-2500 |

45x 2.0 x 7.0 |