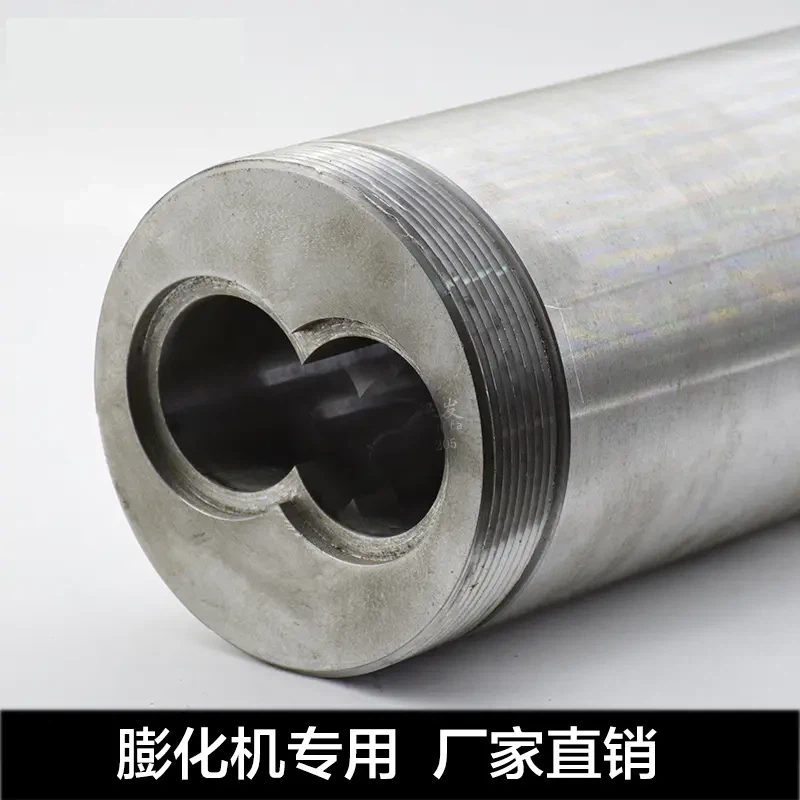

The twin-screw fish feed extruder is a commonly used equipment in modern feed production. Its main function is to extrude and heat treat feed raw materials through two mutually rotating screws in the barrel, thereby processing them into feed pellets of different specifications, tastes, and nutritional components to meet the nutritional needs of fish at different stages. In the twin-screw fish feed extruder, the barrel plays an important role and is one of the core components of the feed extruder. Below is an introduction to the barrel in the fish feed extruder.

1, The function of the barrel

The barrel of a twin-screw fish feed extruder is not just a long tube, it has important mechanical processing functions, heat and mass transfer functions, and heat flow functions, which play a crucial role in the quality of feed processing and the efficiency of fish farming in feed production.

1. Mechanical processing function

The extrusion process of the barrel will cause the feed raw materials to rapidly deform, heat and soften under the high-speed extrusion of the machine rod, resulting in expansion and better plasticity, making it easier to form feed particles. At the same time, the screw clearance inside the barrel can also play a crucial role in the compression and forced evaporation of feed materials, causing them to undergo shear and compression, forming a certain degree of plastic deformation, which provides necessary prerequisites for later processing into feed pellets.

2. Heat and mass transfer function

The friction between the screw inside the barrel and the feed material will cause the heating element to play a necessary role in heating and heat transfer, making the feed material softer when the temperature rises. This requires sufficient heat and mass transfer function inside the barrel to process feed particles. During the processing inside the barrel, the feed raw materials also need to fully absorb the heat emitted by the screw, accelerate the internal molecular movement, transfer, and exchange under high temperature and high pressure, thereby promoting substance conversion and chemical reactions.

3. Thermal flow function

The barrel also plays a crucial role in the transfer, evaporation, and volatilization of liquid fluids during feed processing, allowing for the release and control of moisture. The barrel of the twin-screw fish feed extruder can also be adjusted by the internal moisture and external temperature, making the final feed particles formed during the feed processing isotropic, dense and solid, which is conducive to the packaging, storage and transportation of subsequent feed.

In summary, the mechanical, heat and mass transfer, and thermal flow functions of the core of the barrel are important tasks in the feed production process, and they are also one of the most vulnerable parts in feed processing. How to properly maintain the machine barrel is an important aspect that cannot be ignored in feed production.